Suspended solids accumulate in boiler water . Releasing some of the boiler water at the bottom , already at boiling temperature will immediately flash to a cloud of steam and then fine condensate , to reduce the concentration of potentially corrosive contaminants . Steam locomotives are open loop systems , requiring frequent makeup water which carries contaminants . Even closed loop steam plants utilizing high purity makeup water leak a little steam from valve stem packings , etc. , so plant operators will occasionally blow down the system to get rid of suspended solids .

Steam from high pressure portions of generating stations is actually invisible until cooled to condensate by the cooler air , and I was once told , can cut through flesh at very high escape velocities , not to mention scalding .

Home water heaters , too , even though just in continuous liquid phase should occasionally be partially drained from the bottom to avoid buildup of insulating solids on heat transfer surfaces .

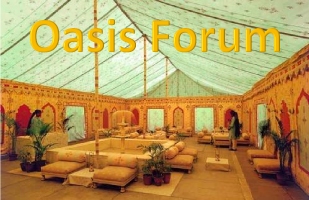

Maya – looks like blowdown at Jim Thorpe

No Comments

No comments yet.

RSS feed for comments on this post.

Sorry, the comment form is closed at this time.